Several preliminary checks are carried out on the spindle (including motor and bearings test, sensor check, tightness test on drawbar etc...) before disassembling.

After disassembling, the geometry of components is checked to define the necessary operation.

The technical report and the overhaul price quotation are issued.

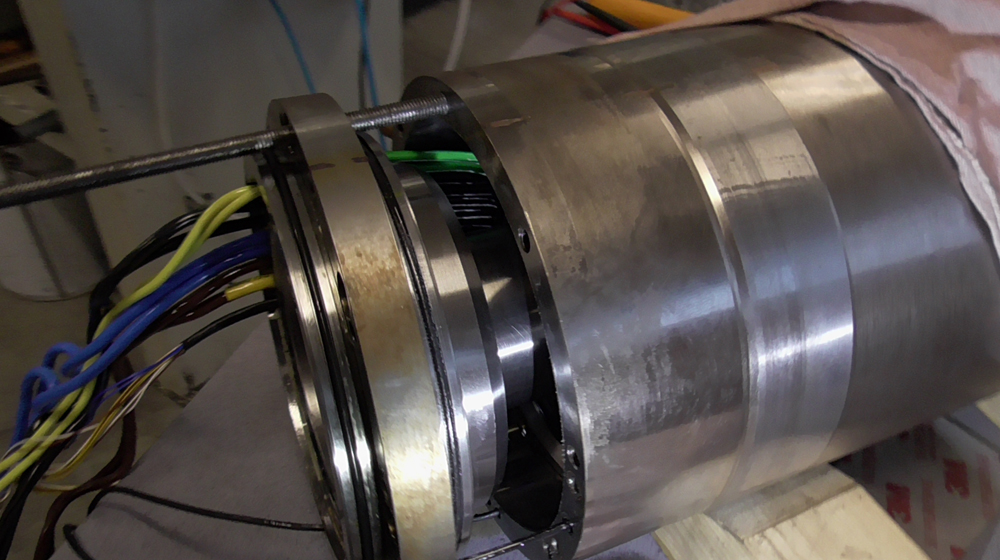

All damaged parts are restored and grinding operations are carried out.

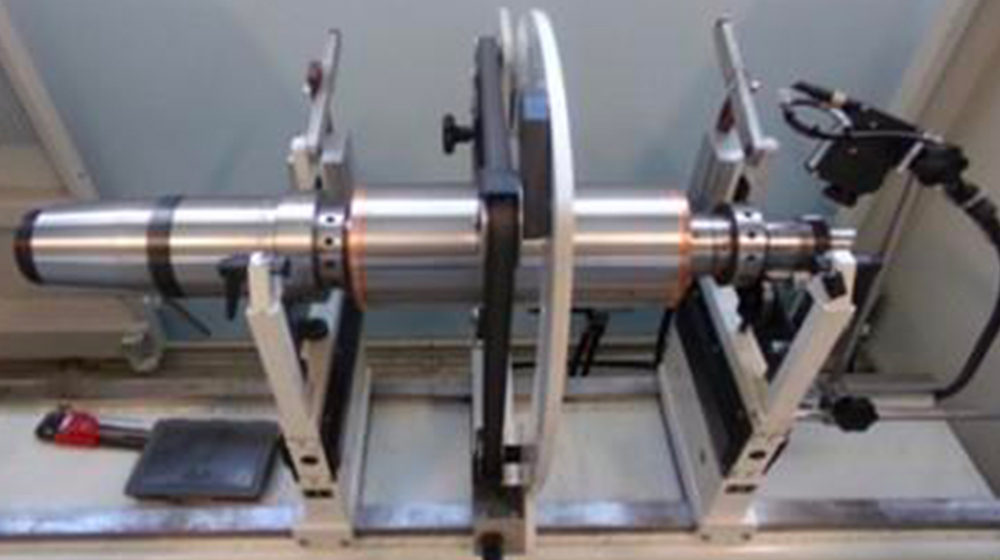

All the rotating parts are balanced before assembly.

We proceed with the assembly after having carefully washed all the parts.

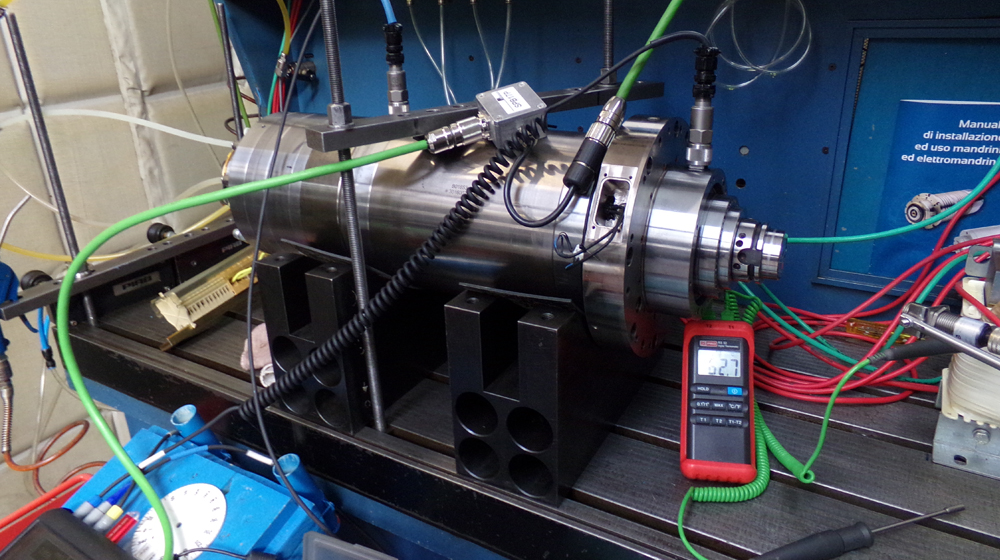

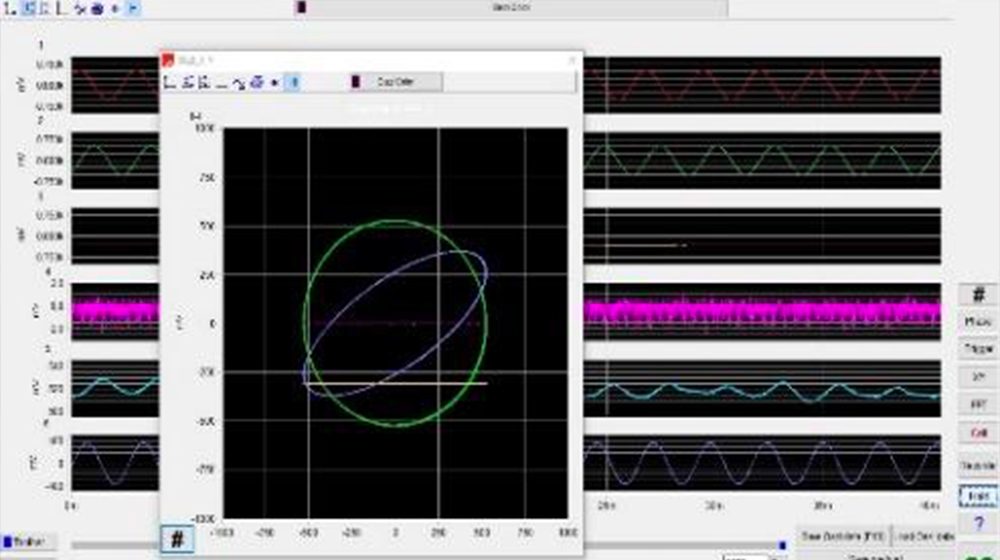

The run-in test is carried out in specific soundproof rooms, where temperature, vibrations and thermal probe values are gauged by.

After sensors calibration, are also certified the encoder reader, the 300 mm rotation error and the clamping force by Power Check.